Commercial Garage Doors, Dock Equipment, Security Screens – Protect Your Business

Whether your business includes a loading dock, service bays or showrooms, there is a commercial garage door and security screens to protect it and make it more efficient. Business owners look to Northland Door Systems for the most comprehensive sales and service support in Madison WI and throughout southern Wisconsin. The commercial lineup includes doors of all sizes with modern openers to match. In addition the company features roll-up fire doors and security screens to protect every space from your parts department to a high school snack bar.

Commercial garage doors are the most visible aspect of a loading dock, shipping/receiving area. Additional heavy-duty components make each bay safe and efficient. If you need any of the performance enhancements to make a loading dock deliver peak performance, we’ve got them.

Where do you need a reliable, commercial grade overhead door? Among the easiest businesses to recognize are:

- Warehouses and distribution centers

- Auto service centers

- Vehicle dealerships

- Manufacturing facilities

- Car washes

- Parking garages

- Apartment complexes

- Municipal buildings

- Schools

- Restaurants

- Mini-ware house/personal storage

Can you add your specific needs to this list?

Heavy-duty garage doors for business fall into two basic groups: traditional sectional overhead doors and steel roll-up doors. Each has its advantages.

Traditional Sectional Commercial Garage Doors

The sectional commercial door has been the standard for decades. Sectional doors come in many size options and are easy to operate. Like the garage door you have at home, they are created from panels that slide up and down on tracks. Unlike the home version, commercial sectional doors are normally made with 14- to 16-gauge steel. The number of panels depends upon the size of the opening. Panels can be solid, include a few windows or be all glass around steel or aluminum frames.

Combining rugged steel and heavy-duty aluminum, commercial doors require powered openers to match. An opener has to be rigorous and strong not only to lift and manage the heavy door, but to do it repeatedly. While in some applications the doors are raised/lowered sparingly, in loading docks and service bays they go up and down often. Fitting the door with an appropriate commercial-grade opener is a must. These large doors are very difficult to operate manually. With the demands you put on your business’s garage doors can you afford to have one out of action because the opener failed?

Sectional Garage Door Advantages

The main advantage of a sectional door is the ability to customize it to fit many openings. Using several panels slotted together they can accommodate many different heights. Modular by design, maintenance and repairs are easier, too. Downtime is productivity and money lost. You need a door that works on demand and can be repaired quickly if it doesn’t, don’t you?

If you’re renovating or expanding an existing facility or building a new one, consider these additional advantages of sectional doors:

- Energy-efficiency – with built-in seals sectional doors prevent drafts.

- Automated opening – easily accommodate a variety of commercial-grade opening systems.

- Enhanced security – with their rugged construction sectional doors are difficult to breach. Even all-glass doors offer security plus visibility.

- Easy maintenance – routine preventive maintenance keeps doors operating at high levels. Damaged doors are repaired with relatively ease, minimizing downtime.

- Great impressions – available in many custom and standard colors to showcase your company’s colors and create an attractive work environment. While curb appeal isn’t as important to a distribution center or service shop, making a positive impression on customers makes sense, everywhere, doesn’t it?

“We are a commercial business and had them replace 3 doors. All aspects were good. The manager providing pricing was good and knew his stuff, and offered some cheaper options to temporarily help some additional doors. The installers were very good too and kept the disruption to a minimum.”

William K.

Sectional Doors Aren’t For Every Location

Although they are still the industry standard, sectional doors aren’t the best choice in every situation. They have disadvantages, including:

- Ceiling space – these big overhead garage doors use tracks running up the sides and horizontally overhead. They need ceiling space and overhead clearance to accommodate the tracks and raised doors.

- NOTE – there are installations where the sectional door tracks direct doors straight up instead of overhead. However, these are only usable in warehouses and buildings with extremely high ceilings.

- Interfere with lighting – when the large overhead doors are open they block nearby ceiling-mounted lights. Loading dock lighting is always a challenge. Limiting available light reduces efficiency.

- More parts – sectional doors have more basic parts and more moving parts than some alternatives (springs, rollers, hinges, etc.).

- Weight – the same rugged construction that makes them good for the job can be a drawback when it comes to electronic opening systems. Openers have to be able to repeatedly lift much heavier loads. A commercial sectional overhead door can weigh nearly 1,000 pounds.

Do these drawbacks cause concern? You do have alternatives. Modern rolling commercial garage doors are gaining popularity. Though sometimes less versatile and adaptable, they offer viable options and positive solutions.

Rolling Commercial Garage Doors – Gaining Popularity

Roll-up garage doors for commercial installations are popular in warehouses, distribution centers and facilities where openings can be standardized. They are proving their value for both new construction and updates. Benefits include:

- Heavy-duty construction – engineered from heavy-duty steel or aluminum rolling doors are equipped with equally heavy-duty hardware. They are durable and withstand the stress of repeated use. When a major manufacturer guarantees its doors will go up/down 50,000 times without failing, you get the idea they’re rugged, don’t you?

- No wasted space – traditional fold-up doors need overhead space for hardware and accessories. Rolling garage doors do not. Roll-up doors simply coil straight up, using very little space above the entry.

- Low maintenance – basic design with few moving parts means less maintenance. Seals around door openings protects mechanical components.

- High-security – metal rolling dock doors, because of their small interwoven panels are strong. They roll and compress and when extended are hard to penetrate.

Insulated Rolling Doors For Added Efficiency

The whims of Wisconsin’s weather are held at bay by including insulation on roll-up garage doors. Not only does insulation keep employees and work areas more comfortable, it helps control energy costs. Keeping out winter blasts is an obvious benefit, but isn’t insulation just as vital on muggy July and August days?

Modern rolling doors like Cornell’s Thermiser® and Thermiser Max® are factory- and field-tested to insure they maintain environmental separation on both sides of the door. Each has full perimeter sealing plus insulation curtains. The doors combine roll up steel construction with the insulating benefits of foam. In addition, insulated doors store just as compactly when open and move effortlessly.

In addition, Thermiser Max doors meet guidelines for Green Building LEED certification. The design allows them to deliver up to 94% less air penetration compared to standard doors. What else does insulation add:

- Reducing outside noise penetration – edge seals help to keep outside noise at a minimum. Individual door panels are thicker, too, so sound doesn’t easily penetrate.

- Quieter inside – insulated rolling garage doors dampen sound inside as well. Whenever doors are going up/down frequently keeping related noise to a minimum is important. Noise contributes to worker fatigue.

- Efficient workplace environment – regulating interior temperatures is a benefit to people, products and equipment. That’s especially important when more and more digital, computerized equipment is employed. You’re using more temperature-sensitive equipment than ever aren’t you?

Specialty Rolling Fire Doors

Rolling fire doors are available to fit openings between indoor spaces, not just entry points. They increase the security of your people and property. The rugged steel doors fit tight from floor to ceiling sealing off smoke and flames. More and more, building codes demand fire doors and municipalities require annual inspections for offices, warehouses and retail space. Northland Door Systems provides regular testing for fire doors. Making sure your doors meet all local fire codes is vital, right?

Roll-up doors consist of metal slats rolling together similar to standard garage door panels. Originals were simply gray. Now, protective baked-on coatings come in several colors. Corrosion protection treatment is also common. Available finishes including:

- Powder coating – a high-tech industrial paint baked into a durable finish.

- Hot-dip galvanizing – a coat of heated zinc added to create a silver finish.

- Cold galvanizing – spraying a zinc solution or powder coating onto metal parts, protecting them from weather and corrosives.

- Type 304 stainless steel – the most versatile and widely-used stainless. Corrosion-resistant it polishes to a bright shine or takes a protective coat of paint.

- Weather seals – limit air coming in/out around the rolling door. For fire doors professional installation is important for a complete seal. Be sure to drop-test seals added after the door goes in.

Installed and operated correctly rolling steel fire doors are safe and effective. But don’t underestimate how heavy and bulky they are. To protect property and staff rely upon professional garage door technicians to review your installations and educate your people. It’s worth the extra effort to protect your people and property, right?

Professional Rolling Fire Door Testing

Most safety procedures rely upon operators knowing how equipment functions and using common sense. Regular consultation with trained technicians provides guidelines for routine checkups that should include:

- Visually inspecting doors for damage or excess wear.

- Making sure everything works – checking locks, fasteners etc.

- Removing obstructions from the door’s track/pathway.

- Opening/closing doors with the opening mechanism – chain, crank or electric opener.

- Inspect springs for wear – if worn or broken, don’t attempt to replace them, call in a professional with the right training and tools.

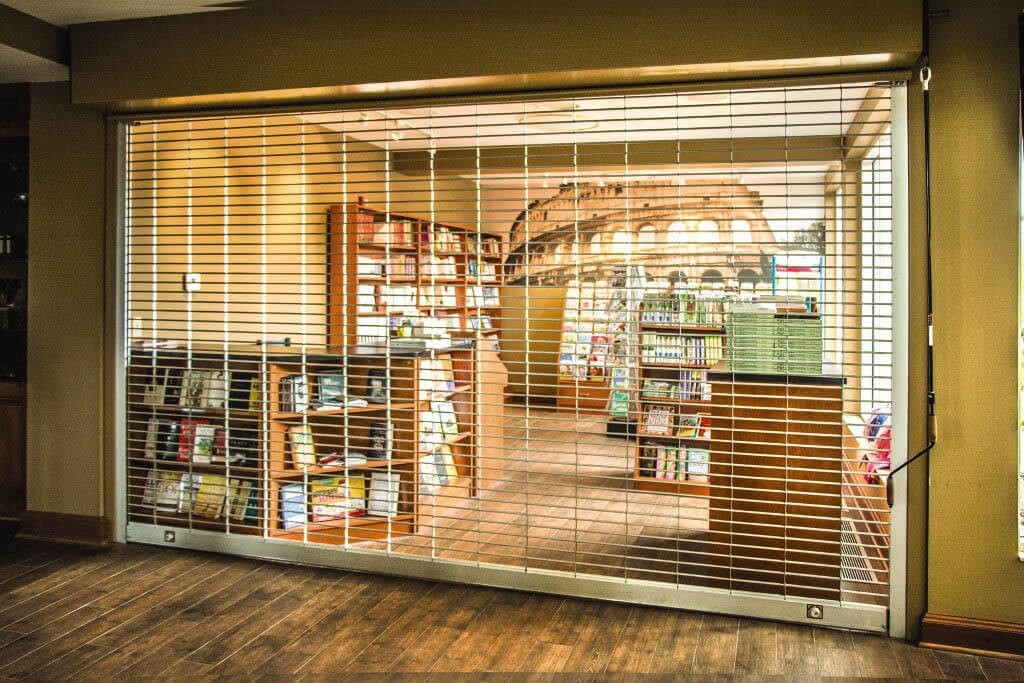

Rolling Security Grills – Expanding On Rolling Door Technology

Taking advantage of rolling door technology, commercial buildings can increase area security with roll-up screens and roll-up grills. These large screen-like installations clearly separate public areas from restricted zones without restricting visibility or air flow. Rolling grills provide security for buildings of all kinds – from closing a dealership’s parts department to shutting down school hallways and mall retail shops. Installations are strong and secure when needed and tuck away out of sight when not needed.

Grills are available in various screen sizes and shapes. In addition today’s options include powder-coated standard and custom colors.

In addition to roll-up configurations, security grills are available that slide side-to-side. When considering installation of the right security screen for your enterprise, keep in mind:

- Choice of materials – while most security shutters and screens are aluminum, stainless or galvanized steel there are wooden models, too. Aluminum is popular where weight is a concern.

- Curtain patterns vary in shape and size.

- Standard widths up to 30 feet.

- Color choices available with protective powder coating.

- Superior slide locks.

- Control units vary from basic pull cords to wall-mounted electric openers and radio/smart phone controlled systems.

When is it time for a new security shutter system? Technology changes so rapidly installations get old in a hurry, don’t they? Evaluate your current system based on these criteria for a good estimate on what you need:

- Shaky operation – is the existing grill hard to open, moving erratically?

- Apparent damage – has your security curtain survived a mishap or attempted break in? If the answer is “yes” replacement may be a wise investment. At least contact Northland Door Systems for a checkup by our factory-trained service techs.

If you want to upgrade the look of your facility and increase security at the same time, check out the latest styles and configurations of grills and shutters.

Beyond Doors – Loading Dock Equipment

There’s a lot more involved in creating a safe and efficient loading dock area than over-size garage doors. No matter if you have one portal or a dozen dock doors, the right levelers, bumpers, seals and structures are critical to efficient operation. Modern engineering has led to push-button dock levelers and remotely operated doors to accommodate bigger and bigger trailers.

Among the latest loading dock equipment for your facility are:

- Dock levelers – various sizes and shapes for almost custom installations.

- Pit levelers

- Dock edge levelers

- Top of dock levelers – most employ powerful hydraulics

- Traditional boards and ramps – brought into the 21stcentury with new lighter but stronger materials

- Dock shelters and seals – help to decrease energy loss around doors as they protect cargo and employees from the elements.

- Truck restraints – larger, heavier trailers need larger, stronger restraints to keep them in place during loading/unloading.

- Safety products – a wide variety of safety-oriented products range from dock bumpers in many sizes and shapes to wheel chocks, dock fans, dock lights and traffic signals for lift trucks and drivers.

Expand, Upgrade Loading Dock Equipment

Does your shipping/receiving area need an upgrade? Or expansion? When you’re planning major changes, consider these ingredients:

- Trucks/trailers coming/going – there are a lot of old and new vehicles in use today. A new loading dock has to be flexible enough to accommodate a variety. Traditionally, trailers sit about 4 feet off the pavement. But some are as low as 20 inches off the ground while others stand about 5 feet high.

- Doors to accommodate wider trailers – trailers are getting longer and wider. Commercial garage doors have to be wide enough to allow easy access to trailers as wide as 8.5 feet with an opening almost 10 feet high.

- Dock levelers – loading docks seldom park trailers with their interior decks even with the dock floor. And positions shift as a trailer gets loaded/unloaded. A mechanical leveling system makes daily operation efficient. Usually rated as “static, rollover and dynamic.” Static and rollover refers to the weight the leveler can safely support. Dynamic refers to the force on the levelers when it’s fully extended. Dynamic rating is an important number to note because it measures everyday working conditions. In general, the longer the leveler, the greater the load it can handle.

Loading Dock Leveler – Preventive Maintenance Pays

It is easy to overlook routine maintenance, service and updates on dock equipment. Undervaluing professional checkups is a fast-track to breakdowns and failures. Replacement costs might be steep, but constant repairs are inefficient and cost more and more in the long-run. Downtime is lost profit!

The first stage of a preventive program is developing a routine maintenance checklist. The second stage is setting up a routine maintenance schedule. Both pay big dividends. Is a timely repair that heads off a failure that creates a crisis worth every minute of advanced planning?

Each maintenance checklist should be geared to your specific operation. Set it up for weekly, monthly and at least semi-annual inspections. In this area, external elements play a big role in daily operations so major cleaning and maintenance to prevent corrosion is mandatory at least twice a year. Even more often if there’s a lot of ice melting chemical, sand and salt used in the area. Consider including these actions in a weekly maintenance inspection program:

- Operate and observe all the dock parts, making sure they’re working properly

- Move levelers to below dock position – clean, visually inspect and line up the rear hinge

- Check the platform and lip for damage or bowing

- Closely look at curb steel and adjacent concrete

- Be sure all safety decals and warnings are in place and readable

- Clean the leveler pit

“Our service tech (Garth) was friendly, professional and efficient. The issue was diagnosed right away and our door works perfectly now.”

Wayne G.

On at least a monthly basis:

- Inspect all welds for cracks

- Inspect all lift arm pins and mounting holes

- Check lip hinge pins and rear hinge pins

- Lubricate all hinges

- Tighten all bolts

- Lubricate counterbalance systems and lift arms

- Inspect frames and bumpers

- Inspect all weather seals

- Carefully inspect conduits, wiring and controls

- Be sure all lighting inside and outside is working

- Pay close attention to truck restraints – preventing trailer “crawl” is vital

Commercial Garage Doors – Installation Critical To Performance

Whether you’re working with sectional or rolling garage doors, security screens or loading dock equipment, installing it right is critical. Your investment is too important to underestimate the value of factory-trained, skilled installers, right? The same goes for repairs.

What does a professional installation and repairs provide:

- Extended life of your equipment

- Reducing the chances of equipment failure

- Protection against unplanned downtime

- Maximizes your repair/maintenance budgets

- Technicians learn and understand your company needs

- Professional technicians help your in-house maintenance staff be more efficient

“The service guy was friendly and did a great job! Took the time to explain what he did. Great customer service! Definitely recommend this company.”

Jane W.

Northland Door Systems brings the latest technology from the best commercial product manufactures to every commercial installation. Our commitment to quality products and service plus our relationship with elite garage door manufacturers insures high-tech solutions throughout southern Wisconsin.

Northland Door Systems repairs, installs and stands behind the best commercial doors, commercial garage door openers and loading dock/warehouse accessories. We cover a wide service area. Take advantage of our decades of experience, call or email Northland Door Systems at 608-251-3627.

Northland Door is the complete resource for sectional garage doors, rolling garage doors and roll-up fire doors, security screens and loading dock equipment in southern Wisconsin. Count on professional installation of commercial garage doors and on-site service anywhere in the Madison WI area.

Northland Door Systems’ commercial garage door suppliers include:

Copyright 2024 Northland Door Systems

Northland Door Systems ● 1800 Tower Street, Prairie du Sac, WI, 53578 ● 608.251.3627